Sustainability

GS Elevator is taking steps towards becoming a ‘Sustainable Global Company’ in line with its Sustainable goals and detailed action plans.

Safety and Health Management

GS Elevator, prioritizing safety as the foremost value in corporate management and practicing sustainable operations, has implemented safety guidelines based on the principle of 'ZERO major accidents,' emphasizing the participation and compliance of all members from top management to employees to drive a safety-oriented health management approach.

(ESH) Environment • Safety • Health Management Policy

GS Elevator prioritizes environmental, safety, and health as the foremost values in corporate management. The company endeavors to prioritize human life at every stage, from product development, manufacturing, installation, to maintenance, aiming to achieve societal values.

-

We comply with environmental, safety, and health laws and international regulations, and strictly maintain internal management standards and continuously improve them.

-

Based on the company value of realizing health and happiness through respect for life, we actively prevent risks through sustainable practices.

-

Through continuous education and training, we cultivate awareness of the environment, safety, and health, and actively participate in activities to strengthen personal and social safety to fulfill our individual responsibilities to achieve our goals.

-

Based on compliance with basic principles, we strengthen a transparent and autonomous environment, safety, and health system through mutual respect and communication.

Safety and Health Management System

GS Elevator, which implements a company-wide environmental, safety, and health management system based on the ISO 14001 standard, has obtained ISO 14001 certification in the elevator development and manufacturing sector.

Download-

Laws

(understanding laws and operation management)- Establishing organizational chart and R&R

- Safety and health document operating procedures

- Safety and health management regulations

- Legal requirements and practical guidelines

- Guide to responding to the Severe Accident Punishment Act

-

Safety and health policies and systems

(preventive management activities)- Managing safety and health activities

- Crisis management response standard manual

- Essential safety rules operation plan

- Safety and health goals and tasks

- (Construction site) safe work procedures

-

Inspection

(Legal obligations)- Safety and health inspection activities

- Daily or weekly employee self-inspection

- Support for external safety and health inspections

-

Education

(legal and competency improvement, safety awareness promotion)- Educating safety and health related laws

- Improving safety and health competency of management and supervisors

- Increasing safety and health awareness of workers

Environmental Safety Activities

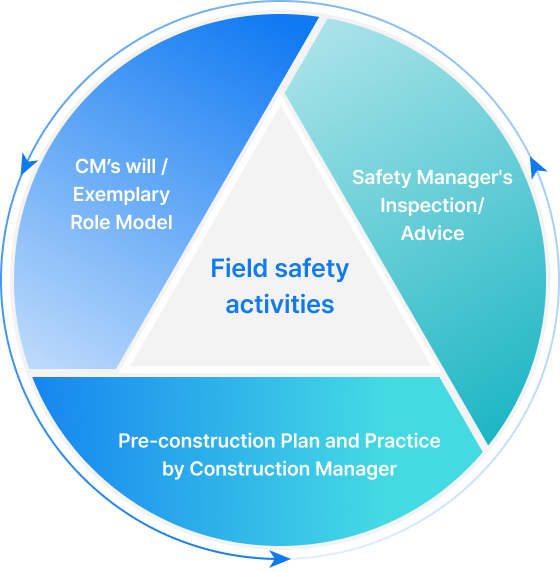

GS Elevator has established a collaborative model where on-site managers, construction supervisors, and safety health managers actively engage in mutual complementarity to embed a unique safety culture throughout the organization and prevent accidents.

- CM shall ensure that the supervisor of management can play his role in consideration of raising awareness of safety and health, preliminary review, and improvement of work patterns.

- CM shall do their best to prevent safety and health problems in construction by thoroughly reviewing the construction plan, checking the implementation of the site, reviewing the construction sequence and structure, and planning for safety and health management.

- Safety and health managers perform appropriate preventive management roles by conducting risk assessments, safety management plan review based on accident case analysis, and supporting construction personnel through worker communication activities.

- This is ultimately aimed at achieving the company's goal of 'ZERO major disasters'.

Safety and Health Activities

The management of GS Elevator is practicing comprehensive safety and health management activities by continuously enhancing employee safety awareness through regular on-site inspections.

| Classification | Hosted by | Attendees | Main agenda |

|---|---|---|---|

| Safety Meeting | Head of a corporation |

|

|

| Weekly Safety Meeting | Director of Installation and Maintenance Headquarters |

|

|

| Safety and Health Committee |

Director of Each Headquarters |

|

|

| Technical Safety Committee | Installation Team |

|

|

Essential Safety Rules

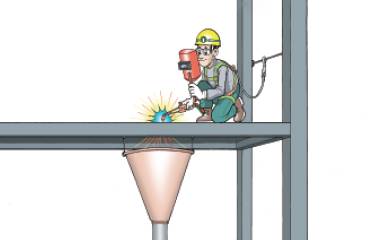

GS Elevator analyzes the causes of disasters that occur at our company and designates essential safety rules to implement on-site safety guidelines. We continuously educate employees and partner companies on essential safety rules through the Safety Innovation School curriculum and safety compliance checks.

-

01

01Install safety belts in places with a risk of falling over 2m and use designated passageways.

-

02

02Install fall prevention facilities at all opening areas

-

03

03Inspect construction equipment before being brought in and used.

-

04

04When handling fire, take steps to prevent sparks from flying and isolate flammable materials

-

05

05When using temporary electricity, install grounding facilities and earth leakage circuit breakers.

-

06

06Prohibit workers from entering the hazardous work area.

| Classification | Fabrication / Production Stage |

Transfer / Departure | Shipping / Loading |

|---|---|---|---|

| Dangerous Point |

|

|

|

| Focused Safety Management |

|

|

|

Safety and Health Activities

GS Elevator ensures that all employees understand and embody the core value of safety management through recurring occupational health and safety education. This effort ultimately contributes to reducing the company's accident rates

-

01Safety Innovation School

GS Elevator is the first in the domestic construction industry to operate the Safety Innovation School, a safety and health experiential education institution operated by GS E&C. Through repeated training, we understand and practice safety management, our top core value, company-wide, ultimately contributing to reducing accident rates. (Facility size: 7,270m² land / Lecture halls: 2 / Experience facilities: 6)

-

02 Safety and Health Education Activities

GS Elevator provides various safety and health education for on-site supervisors, workers, and personnel from partner companies. Through internal and external safety and health professional education programs, we offer diverse education, including online courses, emergency response training and practical exercises, and experiential education

-

03Safety Keepers’ Autonomous Safety Activities

GS Elevator supports employees and partners to practice an autonomous safety management culture.

Selecting and awarding quarterly awards to those who excel in fall accident prevention 3+1 activities and those who wear safety gear

* Fall accident prevention 3+1 activity- ① Wear personal safety gear

- ② Installation and wearing of life line and fall prevention belt

- ③ Speed governor trip operation and safety test

- ④ When removing the winch rope from the car, hang it in two or more places

(sling belt)